Waterjet Cutting

At Augustine Die & Mold, Inc. (ADM), we specialize in full-service ultrahigh-pressure Waterjet Cutting with 5-axis motion for customers seeking high-quality, cost-effective, high-precision parts, from basic and simple designs to the most complex with compound angles and difficult shapes. This method delivers high-precision cuts of virtually any material of nearly any shape and size on a supersized 13-foot x 26-foot cutting table without resultant heat-affected zones, mechanical damage, and delamination by using cold water and up to 94,000 psi of ultrahigh waterjet pressure.

The ADM Approach

- Our team will work closely with you from your drawing or design to your completed waterjet-cut parts to ensure that they are cut in the most cost-effective way to achieve your end-use goals.

- Leveraging our extensive experience, we can waterjet-cut parts with basic, simple designs to the most complex designs that adhere to the strictest specifications, standards, and compliance requirements of a wide array of industries.

- We guarantee to create your parts to the exact CAD/CAM design through the integration of analytical software tools and precision cutting.

- We are committed to achieving Customer, Regulatory, and Statutory Requirements and customer satisfaction by continually improving our organization and the on-time delivery of innovative, cost-effective products and services of the highest quality and reliability.

Streamlining manufacturing processes from concept to completion through expert insight and in-house capabilities

ADM's Expertise, Your Assurance

Waterjet Cutting

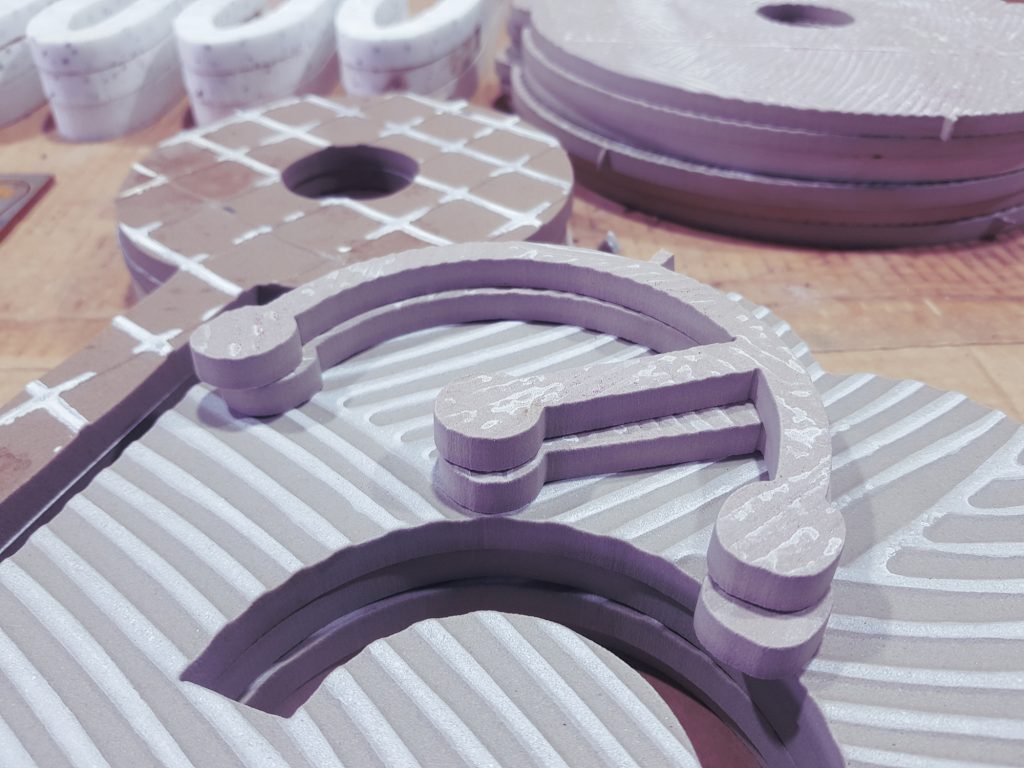

We provide full-service ultrahigh-pressure Waterjet Cutting using our Mach 500 Waterjet by Flow with Dynamic XD® cutting head technology paired with Compass™ to deliver accurate 5-axis motion capable of cutting compound angles with high accuracy. Ideal for complex and difficult shapes such as inside corners, notches, and architectural and artistic shapes from a variety of sheet sizes ranging from 1/16–10 inch thickness. We make high-precision cuts of virtually any material, shape, and size on a supersized 13-foot x 26-foot cutting table without resultant heat-affected zones, mechanical damage, or delamination by using cold water and up to 94,000 psi of ultrahigh waterjet pressure. Technical specifications include linear straightness of +/- 0.0015 in./3 ft., rapid traverse maximum of 700 in./min, and repeatability of 0.001 in. We ensure the maximum use of your material using SigmaNEST® software.

The ADM Advantage

- AS9100:2016 Rev. D Certification | ISO 9001:2015 Certification

- Historically Underutilized Business Zone (HUBZone) Small Business Concern Certification

- International Traffic in Arms Regulations (ITAR) Registration

- Certified Lead Auditor/Quality Systems Manager with 40+ years of experience in Quality Systems

- Modern, state-of-the-art CNC equipment and CAD/CAM software

- 221,000-square-foot facility encompassing production and two large warehouses for raw materials, finished products, and lease space for customers with multiple loading docks for efficient pickups and deliveries

- Conveniently located just off the Pennsylvania Turnpike (I-70/I-76) Somerset Interchange Exit 110 and just off US-219 in the Somerset Industrial Park in Somerset, Pennsylvania

- 24/7 operations capability to meet customers’ demands

At-A-Glance Benefits of ADM’s Waterjet Cutting Services

- Mach 500 Waterjet by Flow with high-precision Dynamic XD® cutting head technology paired with Compass™ for 5-axis motion capable of cutting compound angles with high accuracy

- Cold-cutting method using up to 94,000 psi of ultrahigh waterjet pressure prevents heat-affected zones, mechanical damage, and delamination

- Ideal for complex and difficult shapes such as inside corners, notches, and architectural and artistic shapes

- Cutting of virtually any material, any shape, and any size

- Instant cuts from 1/16 in. to over 10 in. thick

- Supersized 13 ft. x 26 ft. cutting table to accommodate a wide variety of sheet sizes

- Fully integrated FlowXpert® 3D modeling and waterjet pathing CAD/CAM software

- Unparalleled material utilization and nesting efficiency with SigmaNEST® software

- Intricate fine details on expensive material

- Satin smooth edges that don’t require secondary finishing

- 15-ton overhead crane for proper handling of your parts

- High rate of repeatability through a CAD-driven process, not available with most cutting methods

- Rapid Traverse Maximum: 700 ipm (17.8 m/min.)

- Linear Straightness Accuracy: ±0.0015 in./3 ft. (±0.038 mm/min.)

- Repeatability: 0.001 in./in. (0.03 mm)

- Strict quality inspections to meet or exceed the quality requirements for all products and processes

- 24/7 operations capability to meet customers’ demands