Tool & Mold Manufacturing

Design, Build, Repair, and Maintenance

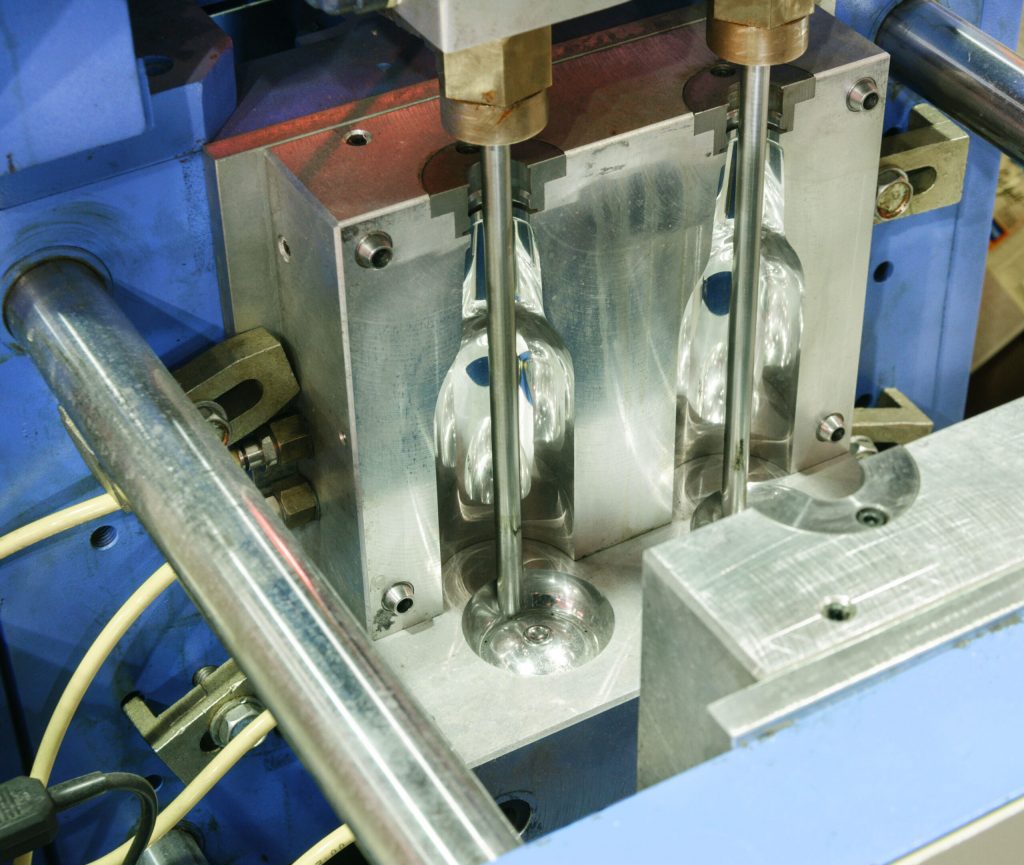

At Augustine Die & Mold, Inc. (ADM), we specialize in full-service Tool & Mold Manufacturing for customers seeking high-quality, cost-effective services in the Design, Build, Repair, and Maintenance of single-cavity molds, multicavity molds, and family molds with complex slides, and prototype molds.

The ADM Approach

- Our team will work closely with you from your concept drawing or design to your completed injection mold to ensure that it is manufactured in the most cost-effective way to achieve your end-use goals.

- Leveraging our extensive experience, we design and build injection molds and produce plastic and metal parts with complex designs and tight tolerances of +/-0.3% that adhere to the strictest specifications, standards, and compliance requirements of a wide array of industries.

- We guarantee to custom build your injection mold precisely to the design of the finished part through the integration of analytical software tools and precision machining.

- We are committed to achieving Customer, Regulatory, and Statutory Requirements and customer satisfaction by continually improving our organization and the on-time delivery of innovative, cost-effective products and services of the highest quality and reliability.

ADM's Core Tool & Mold Manufacturing Services

- CAD/CAM

- Product Design Assistance

- Design for Manufacturability (DfM) Feedback

- Mold Design

- Mold Building

- Mold Sampling

- Mold Repair and Maintenance

- Mold Transfers

Streamlining manufacturing processes from concept to completion through expert insight and in-house capabilities

ADM's Expertise, Your Assurance

Product Design Assistance and Design for Manufacturability (DfM) Feedback

We offer complete design assistance and Design for Manufacturability (DfM) feedback of your conceptual idea of a product to a finished 3D Computer-Aided Design (CAD) model using our state-of-the-art 3D CAD software. With our multiaxis CNC machines and EDM technology, we use that 3D model to develop precise cutter paths and Computer-Aided Manufacturing (CAM) files that we upload to our workstations to machine the actual mold components quickly and accurately.

Mold Design

Our highly experienced engineers will closely review the part design with you for potential design enhancements to improve on manufacturability of your mold and your part. We help you to reduce overall costs while maintaining necessary quality requirements and meeting necessary manufacturing requirements. Before we move to production, our expert mold designer and builder with 30+ years of experience closely reviews and approves your design.

Mold Building

Because the manufacture of the highest quality molded part requires the highest quality, accurately designed and built mold, our expert mold designer and builder custom builds each mold to the exact design of the finished component with precision. Your mold is one of the largest investments that you can make in the manufacturing process, and you can rest assured that our services will result in a favorable return.

Mold Sampling

Before we ship your custom-built molds, we sample them by testing, analyzing, and addressing issues that can affect part moldability such as mold filling, packing, and cooling. And we closely examine and correct any gating, venting, and ejection issues. When your mold goes into production, you can trust that it is production-ready and will mold your parts as designed.

Mold Repair and Maintenance

The life of a mold is just as important to part cost and quality as the design and build of a mold. To support our in-house injection molding operations, we specialize in mold repair and maintenance to prevent mold failures and to lower the overall cost of a molding program. With a variety of processes, such as CNC milling, CNC turning, wire EDM, and welding, we provide accurate, fast, and efficient mold repair and maintenance solutions. Then we quickly return your mold fully repaired so that you can get it back into production.

Mold Transfers

OEMs who experience challenges and poor-performing molding programs with other suppliers elect to move their molding programs to us and trust our experience to mitigate and resolve their problems that often include poor quality, high prices, or long lead times. If you are experiencing similar problems, we have the experience and expertise necessary to perform a full diagnosis to determine the root cause. This service is also critical to customers of our in-house injection molding operations.

The ADM Advantage

- What Most Mold Shops Cannot Match: In-House Injection Molding Operations for Custom Plastic Injection Molding: Having in-house collaborative personnel who thoroughly understand the highly interdependent processes of mold building and injection molding, along with state-of-the-art equipment, enables us to provide what most companies cannot — a true one-stop shop for precision injection molded parts

- AS9100:2016 Rev. D Certification | ISO 9001:2015 Certification

- Historically Underutilized Business Zone (HUBZone) Small Business Concern Certification

- International Traffic in Arms Regulations (ITAR) Registration

- Tool & Mold Manufacturing key staff with median tenure of 30+ years

- In-House Injection Molding key staff with median tenure of 30+ years (API)

- Certified Lead Auditor/Quality Systems Manager with 40+ years of experience in Quality Systems

- Modern, state-of-the-art CNC equipment and CAD/CAM software

- 221,000-square-foot facility encompassing production and two large warehouses for raw materials, finished products, and lease space for customers with multiple loading docks for efficient pickups and deliveries

- Conveniently located just off the Pennsylvania Turnpike (I-70/I-76) Somerset Interchange Exit 110 and just off US-219 in the Somerset Industrial Park in Somerset, Pennsylvania

- 24/7 operations capability to meet customers’ demands

At-A-Glance Benefits of ADM’s Tool & Mold Manufacturing Services

- Modern, state-of-the-art multiaxis CNC equipment to create high-precision molds

- Variety of mold types include single-cavity molds, multicavity molds, family molds with complex slides, and prototype molds

- Product Design Assistance and Design for Manufacturability (DfM) Feedback using 3D CAD software

- Mold Design and Mold Building by expert mold designer and builder with 30+ years of experience

- Mold Sampling to ensure production-ready molds

- Mold Repair and Maintenance to prevent mold failures, increase the life of the mold, and lower overall costs

- Mold Transfers to our company by OEMs experiencing challenges and poor-performing molding programs with other suppliers

- Strict quality inspections to meet or exceed the quality requirements for all products and processes

- 24/7 operations capability to meet customers’ demands

- In-house collaborative personnel who thoroughly understand the highly interdependent processes of mold building and injection molding to provide what most companies cannot — a true one-stop shop for precision injection molded parts