Expert And Innovative Machining And Custom Injection Molding

For Those Who Demand Precision℠

Augustine Die & Mold, Inc. (ADM) | Augustine Plastics, Inc. (API)

Full spectrum of both distinct and integrated services for the core markets of Aerospace & Defense, Energy, Medical, and Water & Wastewater Treatment, and more, with customers ranging from the U.S. Government, small privately owned companies, and Fortune 500 and Fortune Global 500 companies.

Streamlining manufacturing processes from concept to completion through expert insight and in-house capabilities

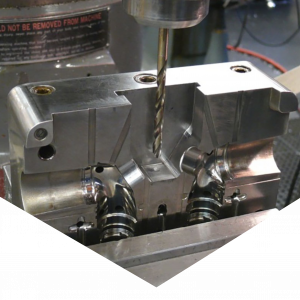

Precision Machining

Full-service Precision Machining that requires expertise and sophistication for customers seeking high-precision, high-quality, cost-effective metal parts with tight tolerances made from exotic metals…

Tool & Mold Manufacturing

Full-service Tool & Mold Manufacturing for customers seeking high-quality, cost-effective services in the Design, Build, Repair, and Maintenance of single-cavity molds, multicavity molds, family molds with…

Waterjet Cutting

Full-service ultrahigh-pressure Waterjet Cutting with 5-axis motion for customers seeking high-quality, cost-effective, high-precision parts, from basic and simple designs to the most complex with compound…

Metal Injection Molding

Full-service custom Metal Injection Molding of single-cavity and multicavity molds for customers seeking high-volume, high-quality, cost-effective metal injection molded parts made with a variety of metal feedstocks…

Plastic Injection Molding

Full-service custom Plastic Injection Molding of single-cavity, multicavity, and family molds for customers seeking high-quality, cost-effective plastic injection molded parts made with commodity and advanced…